Expertise

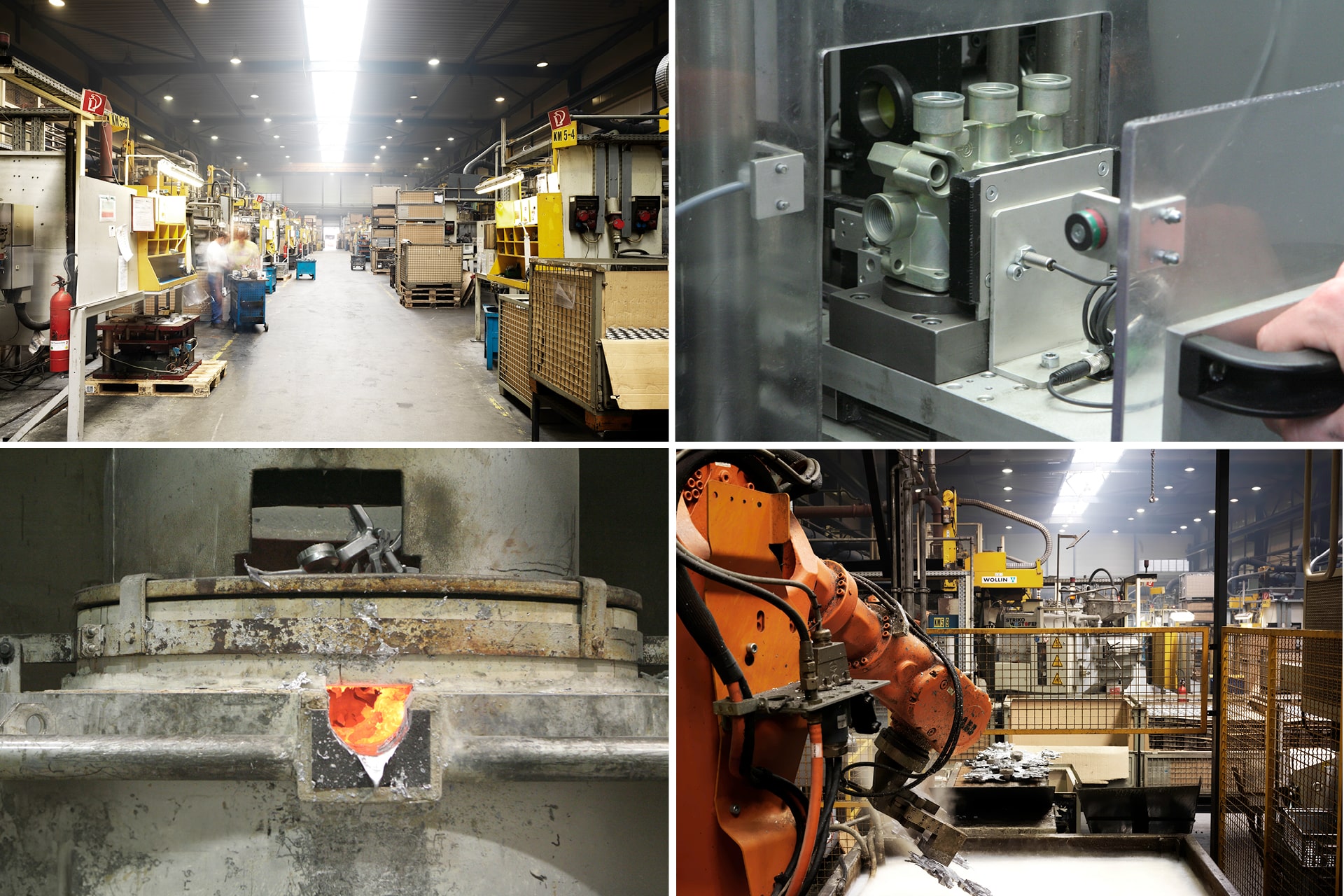

- Location in DE-Bretten Own foundry with melting shop and connected machining centre

- 14 fully automated aluminium - BÜHLER SC 340 - 1,300t

- 3x vacuum technology 2 fully automated zinc - FRECH 125 - 200t 20 CNC machining centres (single & multi-spindle concepts)

- Zeiss measuring equipment (3x Zeiss Prismo, 2x Zeiss Duramax) Deburring (blasting, vibratory finishing + TEM)

- Heat treatment T5 (T6 external)

- Residual dirt analysis Assembly lines Leak test benches Crack and X-ray testing in series

- 2x Powerjet washing centres (aqueous basis)

- 1x Powerline high-pressure washing centre (150 bar / aqueous)

- 1x Hösel washing centre (alcoholic)

- Clean room (air-conditioned)

- Hydac’ rinsing cabinet for analysing residual soiling Microscope with image processing,

- Particle counter DIN ISO 16232-10 or DIN ISO 16232-10 compliant

- Toolmaking for maintenance

Applications

Passenger cars

Truck

Bus

Railway

Agricultural machinery

Construction machinery

Protective technology

Industry

Contact

Contact us

Company Aluminum & Zinc Die Casting

RUPF ATG Casting At our Bretten facility, we stand for unparalleled precision and innovation in the development, manufacturing, processing, and assembly of complex light metal components and modules. We specialize in producing ready-toinstall die-cast products made from aluminum and zinc, serving clients in the automotive, trucking, and industrial sectors. Our success is driven by the seamless integration of cutting-edge technologies and ongoing knowledge transfer, ensuring that we consistently deliver customer-focused, optimal solutions.

Address

RUPF ATG Casting GmbH

Langenmorgen 6

D-75015 Bretten, BW

Tel.: +49 7252 / 964 - 0

Fax: +49 7252 / 964 - 134

Mail: info@rupf-atg.de