Expertise

Mechanical Assemblies

- Processing of steel + stainless steel from bar stock, forgings, castings

- Turning: 25 multi-spindle automatic lathes (10-51mm), 15 turning/milling centres (up to 90mm), 10 sliding headstock lathes (up to 32mm), 6 universal machines (up to 65mm)

- Milling: 50 milling/machining centres (single, double, four-spindle) partly with automation (component size up to 1m, over Ulm up to 4m)

- Other technologies: Grinding (universal, through-feed, flat grinding), broaching/serrating, induction hardening, clean room and various cleaning processes (including ultrasound)

- Typical components: Gearshift parts for gearboxes, housings, air suspension assemblies, shock absorber bearings for railway applications, components for our own assemblies such as ball cups/ball studs for linkage solutions

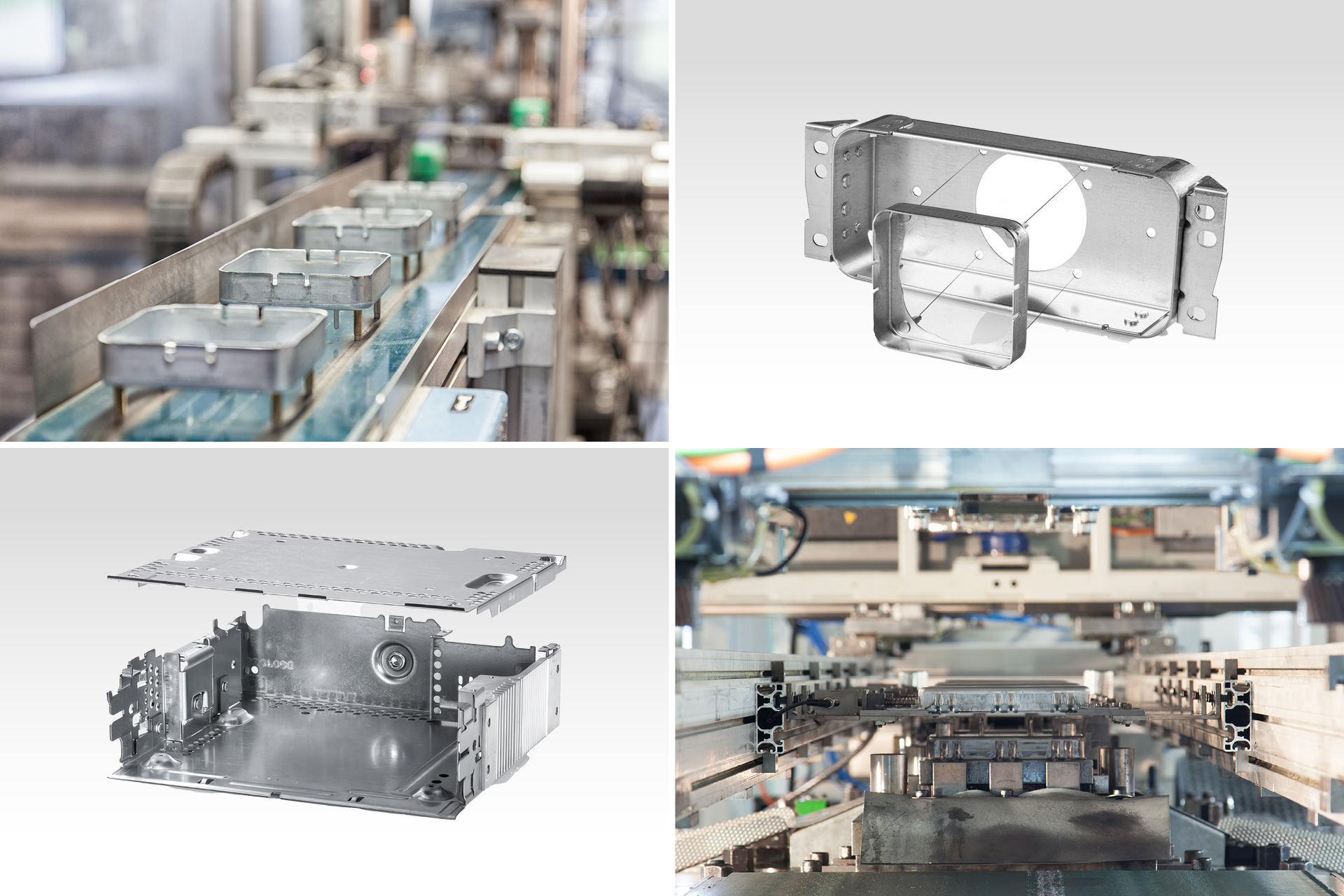

Stamping and forming technology

- Components for the automotive (holders, airbag, interior, steering, chassis components, shielding plates), medical, furniture and electronics industries

- Processing of steel, stainless steel, aluminium, copper, brass, bronze from 0.3-5.0 mm thickness, but also combinations such as sheet metal and cardboard

- A wide range of machinery (hydraulic, eccentric, servo presses) ranging from 100-6,500KN pressing force

- The max. tool length is 4,000mm, the max. strip width 800mm

- Internal vibratory grinding/washing (ultrasound, peroxide) and other downstream processes (various joining processes); external surface processes

- Automated processing of press-fit elements (nuts, bolts, etc.) in the progressive tool

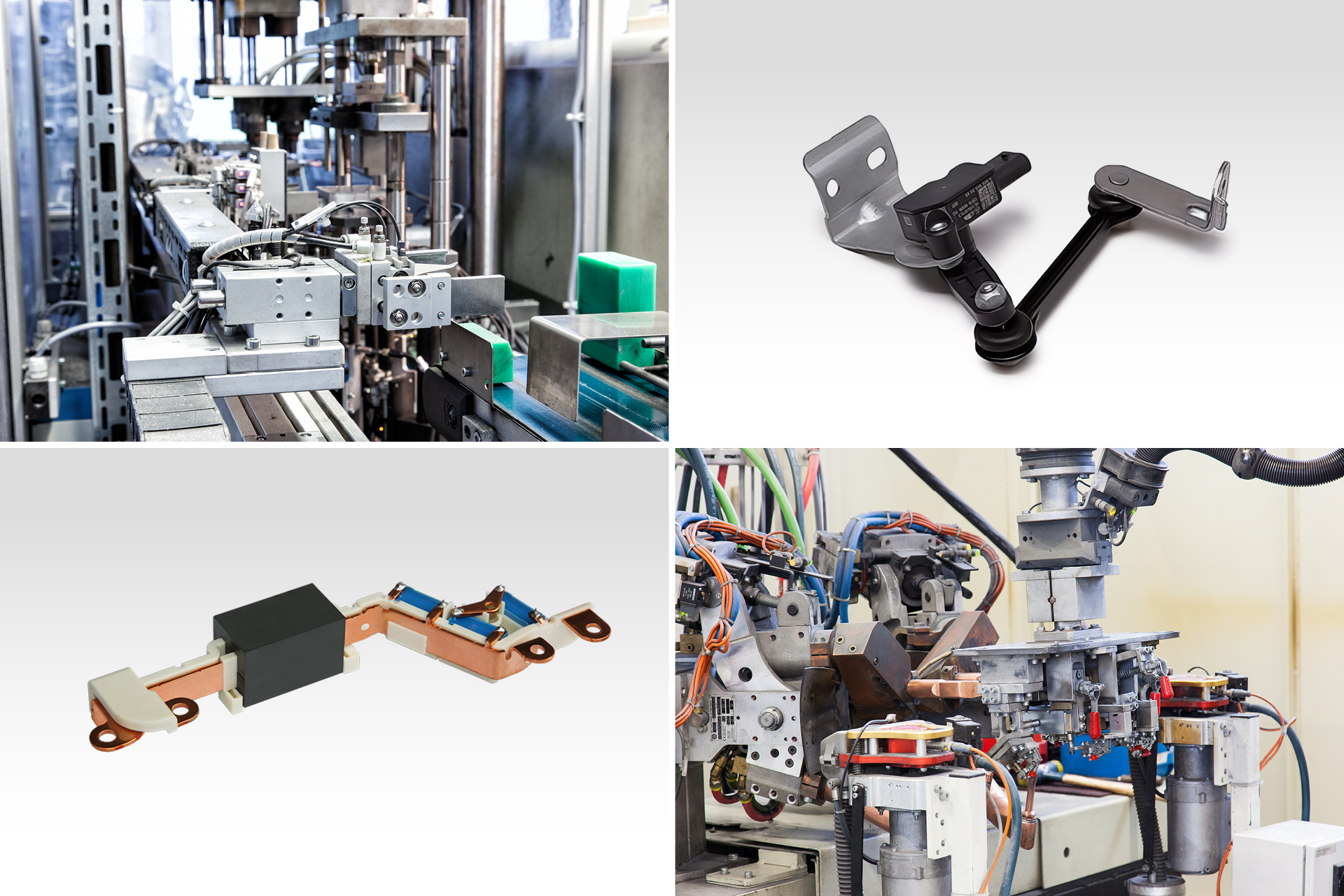

Injection moulding and plastic overmoulding

- Production of injection moulded parts from thermoplastics (POM, PUR, PA) and thermoplastic elastomers (TPE) with injection weights of up to 1,500g

- Processes used: Single and multi-component injection moulding; plastic overmoulding of stamped/die-cast parts both as outsert (plastic injected) and insert technology (overmoulded)

- Typical components such as contact bridges for steering wheel airbags, rods for headlamp levelling, connectors for white goods, overmoulded levers for seat belt deflectors, steering wheel and seat adjustment, bus bars

- Downstream processes such as ultrasonic welding in-house

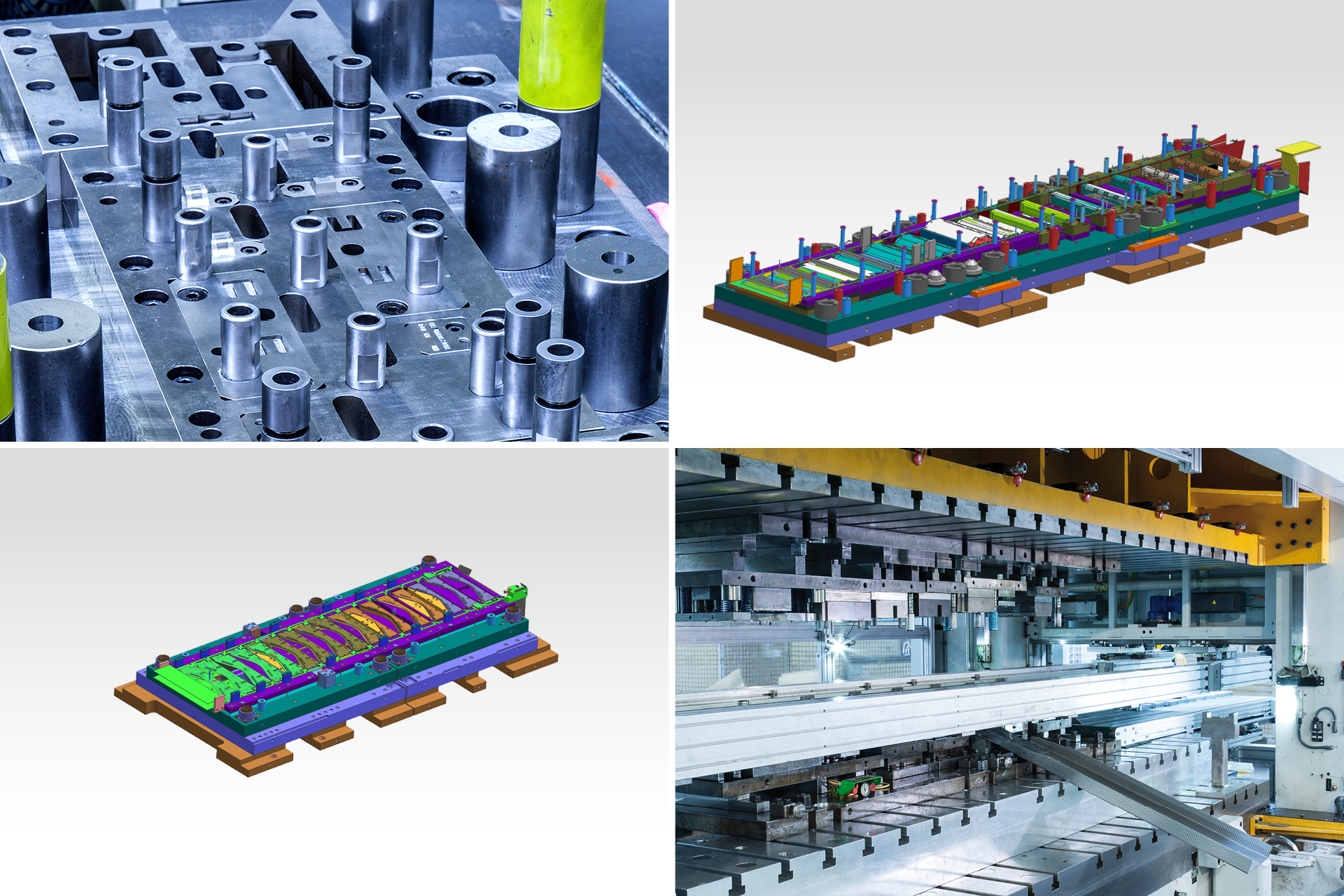

Tool and mould construction

- We manufacture stamping, bending, drawing, progressive and transfer tools with tool lengths of up to 4,000 mm; we also manufacture plastic injection moulding tools and vulcanisation tools for the Group

- All the necessary work steps are carried out in-house; the machinery includes milling, turning, grinding and eroding machines. Grinding and eroding machines, water jet cutting machines, press brakes, etc.

- Design and simulation are carried out in-house using the latest CAD/CAM technology

- We also take on tasks such as component layout and design

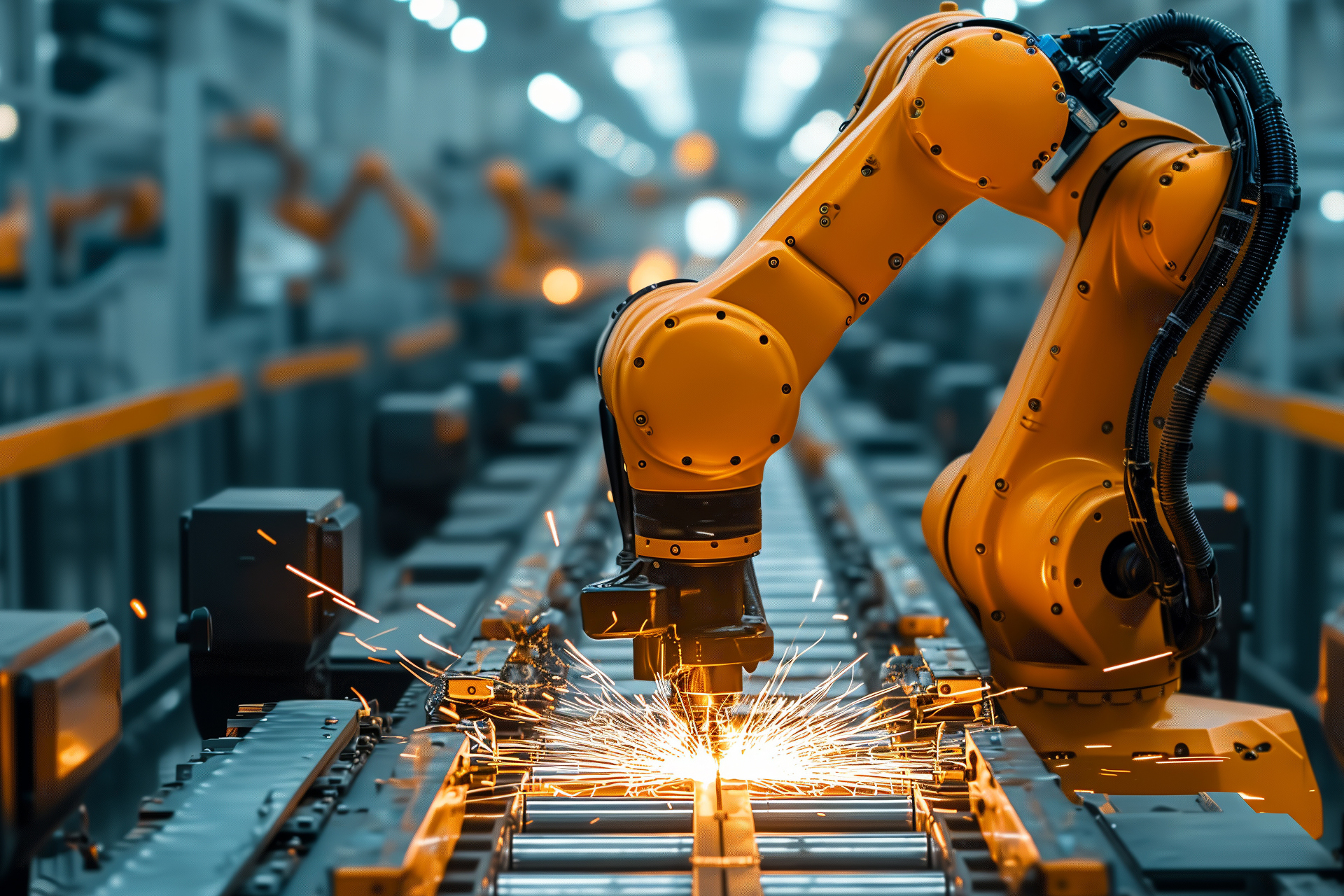

Assembly systems and welding technology

- Building on our diverse manufacturing expertise and knowledge of component layout and design, we also specialise in assemblies

- Partially and fully automated article-specific assembly systems (some of which we build ourselves) guarantee economical and high-quality production

- We offer various (automated) joining technologies such as MIG/MAG/ TIG welding, ultrasonic, laser, capacitor discharge welding, toxen, various riveting processes, etc.

- Product range: linkage solutions for headlamp levelling, door control, cab suspension, load brakes; busbar systems, others

Applications

Passenger cars

Truck

Bus

Railway

Agricultural machinery

Construction machinery

Protective technology

Industry

Contact

Contact us

Group of companies Mechanical assemblies

RUPF SPW Technologies Based in the Ore Mountains, we are your partner for advanced manufacturing technologies across the automotive, medical technology, and electrical industries. Our extensive product portfolio encompasses stamping and forming technology, plastic injection molding, both partially and fully automated welding technologies, and complex fi nal assemblies. With core competencies in process development and the production of stamping and injection molding tools from our own tool shop, we provide innovative solutions and excel in the manufacturing of hybrid assemblies.

Address

RUPF SPW Technologies GmbH

Am Gewerbepark 7

D-08344 Grünhain-Beierfeld

Tel.: +49 3774 / 268 - 0

Fax: +49 3774 / 268 - 3996

Mail: info@rupf-spw.de

BHC Gummi-Metall GmbH Based in Meckenheim, near Bonn, Germany, our company specializes in innovative rubber-metal compounds and vibration damping solutions. We prioritize technical excellence and quality, with a dedicated team that develops and manufactures tailored solutions to meet the highest standards. Our durable and functional products cater to diverse applications, serving clients across sectors including agricultural machinery, construction equipment, rail transport, trucking and trailers, industrial applications, and protective technology.

Address

BHC Gummi-Metall GmbH

Buschstrasse 8

D-53340 Meckenheim, NRW

Tel.: +49 2225 / 92 27 - 0

Fax: +49 2225 / 92 27 - 135

Mail: info@rupf-bhc.de

KHT Fahrzeugteile GmbH Located in Grevenbroich near Düsseldorf, we are a dynamic medium-sized company specializing in high-quality vehicle parts. As a trusted partner to the automotive industry, we provide both national and international clients with bespoke solutions that adhere to the highest quality standards. Our focus on effi ciency and sustainability enables us to tackle complex challenges and contribute to the advancement of future mobility.

Address

KHT Fahrzeugteile GmbH

Industriestraße 13

D-41516 Grevenbroich, NRW

Tel.: +49 2182 / 17 01 - 0

Fax: +49 2182 / 17 01 - 840

Mail: info@kht-fahrzeugteile.de

RUPF Automotive GmbH In Grevenbroich near Düsseldorf, specializes in the production of advanced transmission and gearshift components for the truck, agricultural, and construction machinery industries. Located in Grevenbroich near Düsseldorf, we manufacture complex parts from either cast steel or forged steel blanks. Leveraging state-of-the-art manufacturing technologies and precise production processes, we ensure the highest quality and reliability in our products.

Address

RUPF Automotive GmbH

Alfred-Nobel-Str.5

D-41515 Grevenbroich, NRW

Tel.: +49 2181 / 47 65 - 0

Fax: +49 2181 / 47 65 - 680

Mail: info@rupf-automotive.de

R&P Umformtechnik GmbH & Co. KG As a member of the RUPF Industries Group, our company, based in Ense near Dortmund, provides stamped parts, as well as welding and assembly components for the truck and automotive, construction, sanitary, furniture, and medical

industries. Specializing in small and medium series, we deliver customized manufacturing solutions, leveraging the integrated toolmaking expertise within our group. Our commitment to innovation and state-of-the-art technologies ensures the highest levels of customer satisfaction and reliability.

Address

R&P Umformtechnik GmbH & Co. KG

Harkortstraße 5

D-59469 Ense-Höingen, NRW

Tel.: +49 2938 / 97 73 - 0

Fax: +49 2938 / 97 73 - 379

Mail: info@rupf-rp.de